Indian Journal of Science and Technology

DOI: 10.17485/IJST/v14i22.2087

Year: 2021, Volume: 14, Issue: 22, Pages: 1894-1904

Original Article

M Lenin Sundar 1,*, S Muthukeerthana 2, G Ezhilarasan 3

Received Date:25 November 2020, Accepted Date:11 June 2021, Published Date:02 July 2021

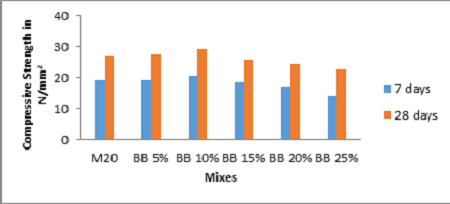

Objectives: To find the optimum percentage replacement of brickbats in concrete by performing fresh and hardened concrete tests and is incorporated into CFDS steel tube column to study its behaviour analytically. Methods: The behaviour of a double skin CFST column with brickbats partially substituting the coarse material with Brickbats. Part of the coarse aggregate was replaced with grouted class I brick bats with percentages of 5 to 25%. A study of the compressive and split tensile strength of concrete was conducted fresh and hardened tests on concrete specimens (cubes and cylinders). Performance of CFDS steel tube column partially replacing coarse aggregate with brickbats is examined analytically using ANSYS. Findings: The compressive and split tensile strength of 10 percent replacement brickbats improved by 8.5 and 13 percent, respectively, while the compressive and split tensile strength of 5 percent replacement brickbats increased by 1.67 and 6 percent, respectively. When compared to nominal cube strength, partially replace brickbats compressive strength increases gradually up to 10% brickbat replacement and then tends to decrease from 15percent brickbat replacement. When compared to different mixtures, it was discovered that adding 10% brickbats increases strength, and this amount was deemed the best mix proportion. The highest load taken by CFDS with 10% brickbats is 649.36kN, whereas standard CFDS is 705.16kN. The CFDS tube was replaced by CFDS tube, which took 1.15 percent more load than brick bats. Novelty/Applications: This research yields good result and can be adopted for the construction of tall composite buildings. This technique will be reduced the self — weight of the structure to some extent.

Keywords

CFDS, brickbats, concrete, confinement effect, ANSYS

© 2021 Sundar et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.