Indian Journal of Science and Technology

DOI: 10.17485/IJST/v16i35.1616

Year: 2023, Volume: 16, Issue: 35, Pages: 2868-2878

Original Article

Chitralekha Nandanwar1*, Santosh Pani1

1Mineral Processing Division, Indian Bureau of Mines, Nagpur

*Corresponding Author

Email: [email protected]

Received Date:03 July 2023, Accepted Date:10 August 2023, Published Date:21 September 2023

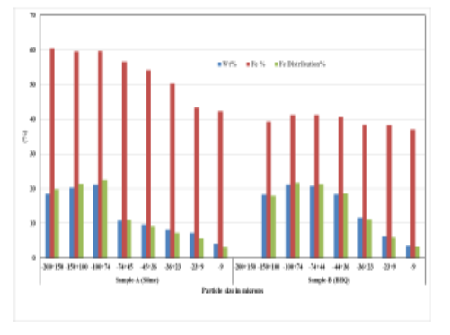

Objectives: To ascertain how desliming affects concentration efficiency of low-grade Indian iron ore and how hydrocyclone process parameters affect desliming effectiveness of low-grade iron ores for their optimum utilization. Methods: Low grade Indian iron ores viz high aluminous type slime (sample A) and siliceous type BHQ (sample B) assaying 56.3% Fe, 7.64% SiO2, 5.14% Al2O3;5.34% LOIand 40.5% Fe, 40.6% SiO2, 0.7% Al2O3, 0.5% LOI are used for this study. The samples undergo beneficiation study by employing the techniques like desliming followed by gravity and magnetic separation for the recovery of iron values. Findings: Two ores appear to behave differently depending on the process parameters. Desliming followed by gravity separation of the ores increases the separation efficiency of the concentration process for both sample A and sample B. Improved iron recovery and grade observed in case of desliming-cum-gravity separation than that of direct gravity separation. The particle size and mineral are dominating the separation response in case of iron ore slime sample A, while in BHQ sample B the dominating factor is particle size only. The grade of deslimed product (hydrocyclone underflow) increased in case of sample A. The grade of deslimed product did not increase in sample B but the particle sizes are more segregated. sample A can be processed to produce an iron ore concentrate with a 65% Fe content and weight(%) recovery of 42 by adopting desliming followed by gravity separation techniques. An iron ore concentrates of 64% Fe with 25 weight (%) recovery can also be obtained from sample B by adopting the same. Novelty & Application: Present investigation establishes the response of different low grade ores in terms of separation with and without desliming. Desliming before concentration will be an easier decision resulting in efficient separation.

Keywords: Iron Ore Slime; BHQ Iron Ore: Desliming; Hydrocyclone; Concentration Efficiency

© 2023 Nandanwar & Pani. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.