Indian Journal of Science and Technology

Year: 2022, Volume: 15, Issue: 38, Pages: 1912-1922

Original Article

M Rajaram1*, S Kandasamy2, A Ravichandran3, A Muthadhi4

1Assistant Professor, Department of Civil Engineering, R&D Institute of Science and Technology, SRM Institute of Science and Technology Ramapuram Campus, Chennai, Avadi, Chennai, Tamilnadu, India

2Associate Professor, Department of Civil Engineering, VelTech Rangarajan Dr Sagunthala R&D Institute of Science and Technology, Avadi, Chennai, Tamilnadu, India

3Former Director, Christ Group of Institutions, Pitchaveeranpet, Puducherry, India

4Assistant Professor, Department of Civil Engineering, Puducherry Technological University, Puducherry, India

*Corresponding Author

Email: [email protected]

Received Date:28 January 2022, Accepted Date:07 June 2022, Published Date:14 October 2022

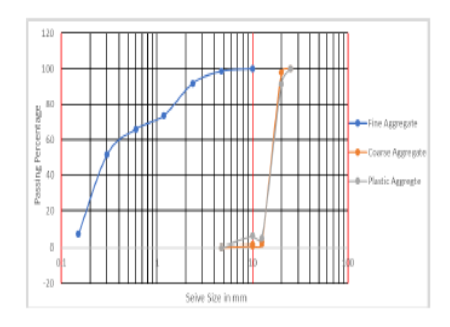

Objectives: The purpose of the present study is to examine the thermal and impact behaviour of the concrete containing polystyrene waste as aggregates. Methods: The concrete specimens were cast and cured in a conventional way to examine the mechanical behaviour of the concrete. A separate equipment was prepared to determine the impact strength of the concrete as per ASTM D5420-21. The thermal behaviour of the concrete with plastic aggregates were also examined with reference to IS 7861-1 (1975). Artificial Neural Network was also used to predict and compare the properties between both the conventional and plastic concrete. Findings: The mechanical behaviour of the concrete behaves well at Mix 2 when compared to other mixes. The impact strength of the concrete was found to be 98.375 J at Mix3 which was 20.69% higher than the Mix2. At Mix2 the 7 days compression strength in elevated temperature is 16.79 N/mm2 which was 4.8% higher than the Mix 1 and 31.74% higher than the Mix 3. At 28 days, the compressive strength of concrete containing 50% replacement of aggregate exposed to temperature 50oc for 24 hours is 26.84 N/mm2 which shows a better result and resistance in the thermal condition than the other mixes. ANN also gives reliable predicted values which exhibits a clear relation with the inclusion of the plastic aggregate and concrete matrix with some minimum errors. Novelty: From the experimental investigation it was observed that the plastic concrete fails in the transition zone of concrete due to the weaker bonding between the plastic aggregate and cement matrix. The plastic aggregate has not undergone any crushing failure in the concrete specimens when compared to the conventional aggregate. Thus, this solid polystyrene waste can be used as an alternative material for coarse aggregate in concrete.

Keywords: Waste plastic; Modified concrete; Mechanical properties; Impact Strength; Thermal behaviour

© 2022 Rajaram et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.