Indian Journal of Science and Technology

DOI: 10.17485/IJST/v13i46.1858

Year: 2020, Volume: 13, Issue: 46, Pages: 4555-4563

Review Article

Essam R I Mahmoud1,2*

1Department of Mechanical Engineering, Faculty of Engineering, Islamic University of Madinah, 41411, Saudi Arabia

2Central Metallurgical Research and Development Institute, Cairo, 11421, Egypt

*Corresponding Author

Email: [email protected]

Received Date:13 October 2020, Accepted Date:13 December 2020, Published Date:19 December 2020

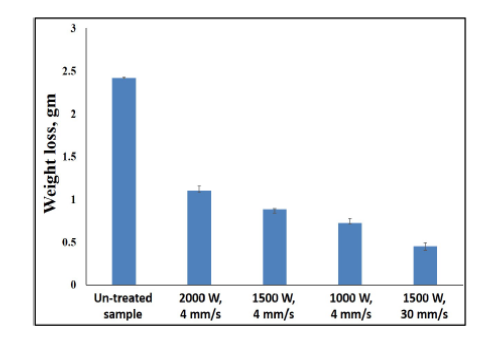

Background/Objectives: The poor wear resistance of pure titanium has significantly limited its industrial and biomedical applications, especially when it is used in severe conditions. To overcome this limitation, surface treatment must be done to improve the wear resistance without negatively affect its excellent corrosion resistance. Methods: To prepare titanium for use under severe wear and friction conditions, its surfaces were laser melted using YAG Fiber laser at powers of 1000, 1500 and 2000 W, and travelling speeds of 4 and 30 mm/s. The processes were conducted in argon atmosphere. Findings: In all cases, three zones were observed: melted zone, heat-affected zone and base metal. The increase of the power and/or decrease of the travelling speed caused increases in the depths of the melted zones. Acicular martensite a’ structure was observed within the melted and solidified zone. A hardened surface layer of 445 HV with improvement of 62%, with reference to CP-Ti base metal, was produced by application of the treatment at power of 1000 W and travelling speed of 4 mm/s. When the travelling speed with increased to 30mm/s, the surface hardness reached 710 HV. The depth of hardened layer was increased from nearly 0.6 mm to 0.8 mm by increasing processing power from 1000 W to 2000 W at travelling speed of 4 mm/s. Remarkable improvements in wear and corrosion resistances of the treated specimens were achieved.The weight losses of the un-treated substrate were almost 5 times (2.4 gm) of the laser treated sample at 1500 W and 30 mm/s (0.5 gm). For corrosion, the corrosion potentials were shifted to more positive values and the corrosion current was shifted to more negative values for the laser treated sample at 1000W compared to the un-treated sample. Applications: the findings will widen the application of pure titanium in many biomedical and industrial fields.

Keywords: Commercially pure titanium; surface microhardness; wear resistance; corrosion resistance; laser surface melting

© 2020 Mahmoud.This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.