Indian Journal of Science and Technology

DOI: 10.17485/IJST/v17i14.3148

Year: 2024, Volume: 17, Issue: 14, Pages: 1464-1473

Original Article

Mohammed Naser Farooqui1*, Nilesh G Patil2, Abhay S Gore3

1Research Scholar, Department of Mechanical Engineering, Maharashtra Institute of Technology, Aurangabad, Maharashtra, India

2Director, Maharashtra Institute of Technology, Aurangabad, Maharashtra, India

3Assistant Professor, Maharashtra Institute of Technology, Aurangabad, Maharashtra, India

*Corresponding Author

Email: [email protected]

Received Date:13 December 2023, Accepted Date:13 March 2024, Published Date:03 April 2024

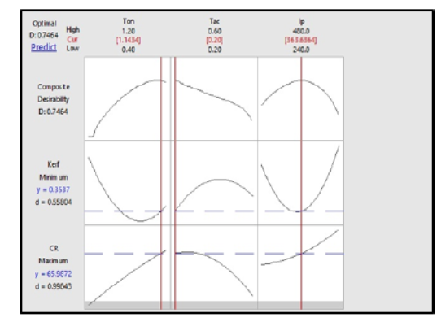

Objective: To maximize the cutting rates and to minimize and width of cut (Kerf) by optimizing the process parameters for wire EDM machining of Si3N4-TiN ceramic composite utilizing zinc coated brass wire optimizing the process parameters by applying Response Surface Methodology using Central Composite Design Technique. Methods: The input parameters, namely, peak current, short pulse duration, and pulse on time duration were varied over five different levels, in order to conduct the studies. The distinctive response characteristics, such as cutting rates and width of cut, are investigated, and optimized using Response Surface Methodology (RSM), which is based on Design of Experiments (DOE). ANOVA was applied to both predictive modeling and the identification of significant variables in order to assess the effectiveness of the model. In the experiments, a coated brass wire electrode was employed in the center composite design. Findings: Comparing the cutting rates with a plain brass electrode, the increases are 4.39% and 16.67%, respectively. The pulse-on time and pulse current are recognized as the two most crucial input parameters; cutting rate rises with increasing current. A coated brass wire with negative tool polarity achieved a maximum cutting rate of 69.72 mm2/min at a peak current of 320A, 1.2 μs of on time pulse duration, the ideal Kerf of 0.35mm was obtained. The % error of RSM predicted and actual is 5.36% for cutting rate and 1.05% for Kerf. Novelty: There is no literature available on the machining of Si3N4-TiN using coated brass wire, for Kerf width and cutting speeds. The zinc-coated brass wire electrode improves the cutting rates and reduces the Kerf significantly for Si3N4-TiN ceramic composite.

Keywords: Si3N4-TiN, CR, Kerf, RSM, ANOVA

© 2024 Farooqui et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.