Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 9, Pages: 811-818

Original Article

K Sadhana1*, K Suguna2, P N Raghunath3

1Research Scholar, Department of Civil and Structural Engineering, Annamalai University, Chidambaram, 608002, Tamil Nadu, India

2Professor, Department of Civil and Structural Engineering, Annamalai University, Chidambaram, 608002, Tamil Nadu, India

3Professor (Retd.), Department of Civil and Structural Engineering, Annamalai University, Chidambaram, 608002, Tamil Nadu, India

*Corresponding Author

Email: [email protected]

Received Date:11 January 2024, Accepted Date:24 January 2024, Published Date:22 February 2024

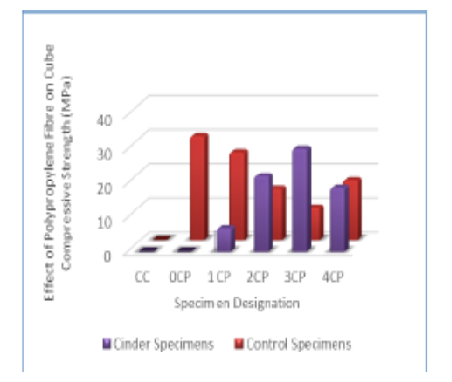

Objectives: The present work examines the viability of using industrial solid waste, like cinder, to create lightweight aggregate concrete. Utilizing cinder aggregate as a substitute material for coarse aggregate in producing concrete not only helps in the conservation of natural resource but also provides a feasible solution for solid waste management. Method: The mechanical characteristics of cinder based lightweight concrete were improved by the inclusion of polypropylene fibre as micro-reinforcement, in volume proportions of 0.1%, 0.2%, 0.3%, and 0.4%. The laboratory tests that were conducted on the polypropylene fibre reinforced cinder based lightweight concrete included compressive strength test on cube specimen and cylinder specimen, flexural strength test on prism specimen and modulus of elasticity test on cylinder specimen. Findings: The findings show that cinder aggregate can be satisfactorily utilized as an alternate material to coarse aggregate in the production of lightweight concrete. It has been found that 0.3% of polypropylene fibre was the ideal dosage of micro-reinforcement that can be incorporated in lightweight concrete. Novelty: Further, a multiple linear regression (MLR) model was suggested to evaluate the performance parameters of the fibre-reinforced lightweight concrete, providing an alternative to the time and material consuming experimental works. Scatter plots and Statistical indicators such as R2, RMSE and MAPE indicated that the model demonstrated a strong correlation between the predicted values and the experimental results.

Keywords: Cinder aggregate, Lightweight concrete, Mechanical characteristics, Micro reinforcement, Regression model

© 2024 Sadhana et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.