Indian Journal of Science and Technology

Year: 2020, Volume: 13, Issue: 38, Pages: 3960-3969

Original Article

S K Nanda1*, S Pani1, D Beura2

1Assistant Ore Dressing Officer, Mineral Processing Division, Indian Bureau of Mines, Nagpur, 440016, India

2Associate Professor, P.G. Department of Geology, Utkal University, Bhubaneswar, 751004, India

*Corresponding Author

Email: [email protected]

Received Date:03 September 2020, Accepted Date:29 September 2020, Published Date:22 October 2020

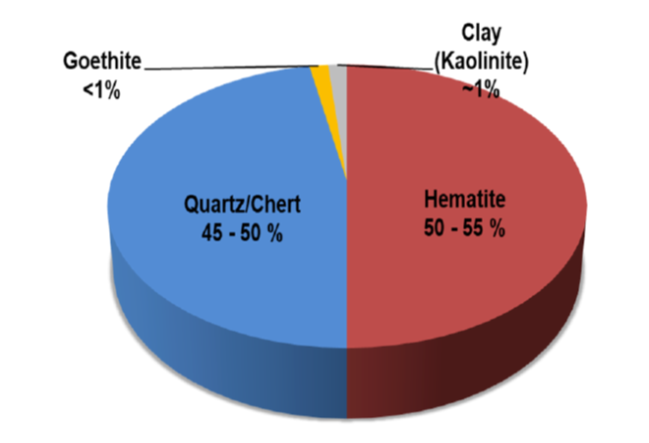

Background/Objectives: Due to soaring demand and rapid depletion of high-grade iron ores, lean grade iron ores of India like BHJ and BHQ needs to be utilized through suitable beneficiation techniques. Methods: Banded Hematite Jasper (BHJ) sample of Bonai-Keonjhar belt (BK belt), Odisha, India assayed 35.3 % Fe, 47.1% SiO2 and 0.96% Al2O3 was investigated in respect of mineralogy, liberation characteristics and chemistry to finding out its optimum beneficiation potential. In the present investigation, efforts have been made to characterize the BHJ sample with reference to its beneficiation response. The sample was subjected to various beneficiation operations like Jigging followed by hydrocyclone, two-stage tabling and magnetic Separation. Findings: Mineralogical studies indicate that quartz and hematite are the major mineral phases, whereas goethite, martitized magnetite and clay (kaolinite) are present in very minor amounts. The liberation characteristic indicates that the average band thickness of Iron bearing mineral is of 1680 microns and 80% of the iron bearing minerals are liberated at -105 microns size. The two stage tabling of jig concentrate with desliming gives better outcome as compared with direct tabling of jig concentrate. An iron ore concentrate assayed 64.5% Fe, 5.6% SiO2 and 0.80% Al2O3 with wt% recovery of 23.2% can be obtained from two stage tabling. Another concentrate from magnetic separation of table middling and hydrocyclone assayed 63.2% Fe, 7.2% SiO2 and 0.7% Al2O3 with wt% recovery of 12.4% can be obtained. Novelty/ Application: Here a conventional beneficiation flow sheet is developed with a finding that, in order to beneficiate ore like banded hematite jasper (BHJ), an integral characterization approach is very much essential. Both of the concentrates obtained through the flow sheet assayed 64% Fe, 6.2% SiO2 and 0.7% Al2O3 with a wt% recovery of 35.6% can be utilized as a feed stock for pellet making in iron ore industries.

Keywords: Banded Hematite Jasper (BHJ); mineral beneficiation; wet high intensity magnetic separator (WHIMS); jigging; Bonai-Keonjhar belt

© 2020 Nanda et al.This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee).

Subscribe now for latest articles and news.