Indian Journal of Science and Technology

Year: 2024, Volume: 17, Issue: 9, Pages: 804-810

Original Article

D Nirosha1*, C Sashidhar2, K Narasimhulu3

1Research Scholar, Department of Civil Engineering, JNTUA, Ananthapuramu, Andhra Pradesh, India

2Professor, Department of Civil Engineering, JNTUA, Ananthapuramu, Andhra Pradesh, India

3Professor, Department of Civil Engineering, Sree Vidyanikethan engineering college, Andhra Pradesh, India

*Corresponding Author

Email: [email protected]

Received Date:05 January 2024, Accepted Date:27 January 2024, Published Date:20 February 2024

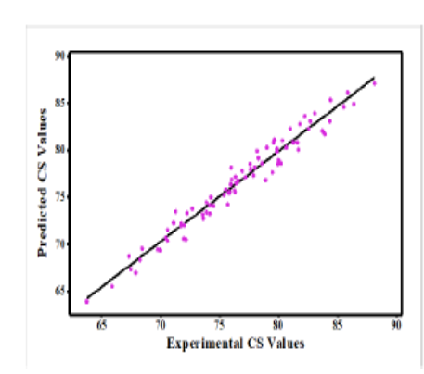

Objectives: In this study, a model was developed to predict the compressive strength of High Strength Concrete (HSC) mixed with silica fume using Response Surface Methodology (RSM). This study investigated the effects of cement, water, Silica Fume (SF), Coarse Aggregate (CA), and silica fume-cement ratio (SF/C) on the 28-day compressive strength of HSC. Silica fume is added with varying amounts of SF (5% to 25%) to cement content. Methods: Response surface methodology (RSM) was performed to investigate the influence of independent variables on the compressive strength of HSC. Findings: Analysis of the response surface plot reveals a remarkably low error percentage of less than 5%. This reveals a high degree of confidence (95%) in the model's accuracy. This study yielded a coefficient of determination (R2) of 0. 9968. It is observed negligible deviation between predicted and actual 28-day compressive strength values, indicating high model accuracy. Novelty: The predicted equation is reasonably predicting the compressive strength of high strength concrete.

Keywords: High strength concrete, Response surface methodology, Silica fume, Compressive strength, Prediction model

© 2024 Nirosha et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.