Indian Journal of Science and Technology

DOI: 10.17485/IJST/v15i45.1824

Year: 2022, Volume: 15, Issue: 45, Pages: 2508-2514

Original Article

Dandapani1*, K Devendra2

1Research Scholar, Department of Mechanical Engineering, VTURRC Belagavi, Belagavi, Karnataka, India

2Professor, Department of Mechanical Engineering, SKSVMACET - Laxmeshwar, Gadag, Karnataka, India

*Corresponding Author

Email: [email protected]

Received Date:09 September 2022, Accepted Date:13 October 2022, Published Date:09 December 2022

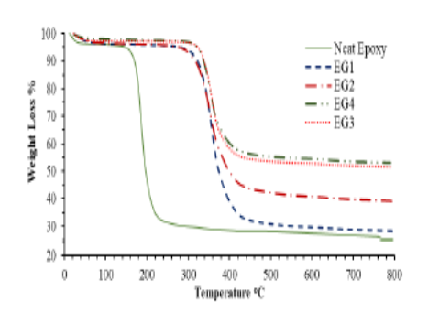

Objective: Epoxy is a commonly used material for electronic components packaging, yet its inherent thermal resistance can’t meet rising demands. To improve the thermal performance of Epoxy material, the high thermal conductivity of Graphene nanoparticles interspersed into the epoxy matrix. This paper focuses on experimental results on the thermal properties of Graphene-based epoxy composite. Methods: Scanning Electron Microscopy and Energy Dispersive X-Ray Spectroscopy used for elemental analysis. Guarded Comparative Longitudinal Heat Flow Technique, thermogravimetric analysis, digital scanning calorimeter, and thermogravimetric analysis used to determine thermal conductivity, Coefficient of thermal expansion, specific heat capacity and thermal stability as per ASTM standard respectively. Findings: Thermal decomposition temperature enhanced from 170 0C of pure epoxy to 329 0C for epoxy with 0.5 wt% of Graphene nanofiller, and it increased with an increase in filler loading, hence proving the thermal stability of composite improved with the addition of graphene nanoparticles. Maximum thermal conductivity of 0.43 W/mK and thermal diffusivity of 0.686 x10-6 m2/s had recorded for 2 wt% of Graphene additives. Linear thermal expansion coefficient and specific heat reduce for the composite material with an increase in filler. Therefore, this indicates heat resistivity improved with minimum heat storage. An increase in stability, conductivity, and diffusivity with the decrease in expansion coefficient and specific heat capacity due to heat proves a favourable factor for thermally conductive material. Novelty: The easy method employed for material preparation, also the use of ultra-low filler content tends to reduce composite cost. Graphene-based Epoxy composites with modified properties represent a conceivable packaging material.

Keywords: Thermal Properties; Epoxy composites; Specific heat; Thermal conductivity; Thermal diffusivity

© 2022 Dandapani & Devendra. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.