Indian Journal of Science and Technology

Year: 2023, Volume: 16, Issue: 6, Pages: 409-419

Original Article

K Ramesh1*, S Ramanathan2, B Vinod3

1Research Scholar, Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar, Chidambaram, 608 002, India

2Professor, Department of Manufacturing Engineering, Annamalai University, Annamalai Nagar, Chidambaram, 608 002, India

3Associate Professor, Department of Mechanical Engineering, Siddharth Institute of Engineering & Technology, Puttur, 517583, India

*Corresponding Author

Email: [email protected]

Received Date:04 November 2022, Accepted Date:17 January 2023, Published Date:11 February 2023

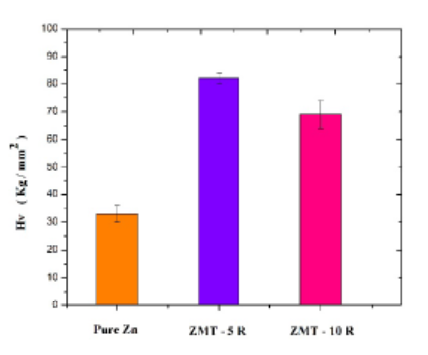

Objectives: To investigate the mechanical and microstructural behaviour of zinc hybrid composites. Zinc alloys are utilized in biomaterial development for implant applications due to their suitable corrosion properties. However, the advantages connected with hybrid reinforcements suggest further research. The objective is to determine the impact of Hydroxyapatite (HA) and Calcium Silicate (CS) derived from biowaste as hybrid reinforcement in Zn-1Mg- 0.2Ti alloy. The influence of hybrid reinforcement (HA&CS) was assessed in various weight percentages. Methods: Synthesis of the reinforcement (HA&CS) involved 10h milling and calcination at 1000ºC. Pure Zinc and Zn-1Mg-0.2Ti alloy with 5 wt. % and 10 wt. % (HA and CS) biomaterials were fabricated by the squeeze casting process. Hardness tests of the cast samples were conducted with a 1 kg (Hv) force and a 15-second dwell time. The compressive test was performed as per ASTM E9-19, with a ram speed 0.5mm/min. Findings: Results suggest that, among all three cases, Zn-1Mg-0.2Ti-(2.5 HA / 2.5 CS) composite exhibited favourable mechanical and microstructural properties. The Zn-1Mg-0.2Ti-(5 HA / 5 CS) composite density was 5.52 kg/m3, a significant 25% decrease compared to pure zinc metal. The Hardness value of Zn-1Mg- 0.2Ti-(2.5 HA / 2.5 CS) was 82Hv, which is 148% increase compared to pure zinc metal (33Hv). The compression tests demonstrated that the Zn-1Mg- 0.2Ti-(2.5 HA / 2.5 CS) exhibited the highest ultimate compression strength (364 MPa) and toughness modulus (131 MPa) due to sufficient adherence of the reinforcement with the matrix. Novelty: The novelty of the study was to introduce hybrid reinforcements (HA and CS) in the Zn-1Mg-0.2Ti alloy to increase its hardness and compressive strength. Zn-1Mg-0.2Ti-(2.5 HA / 2.5 CS) is a new hybrid composite compared to recent biomaterials. Furthermore, it can be recommended for implants in orthopaedic surgical applications.

Keywords: Zinc Composites; Biodegradable Materials; Hydroxyapatite;Calcium Silicate (Wollastonite); Compressive Strength

© 2023 Ramesh et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Published By Indian Society for Education and Environment (iSee)

Subscribe now for latest articles and news.